Reactive processes for the valorization of polyactide

Fanny Bonnet

Directrice de Recherche CNRS, Univ. Lille, CNRS, INRA, ENSCL, UMR 8207 - UMET - Unité Matériaux et Transformations

Le 22 janvier 2026 à 13h00, Amphi Fournel

Abstract:

Among the different biobased materials available on the market, poly(lactic acid) (PLA) is becoming more and more competitive and accounts for about a quarter of biodegradable bioplastic production. This biocompatible polyester is synthesized either by direct polycondensation of lactic acid, resulting from the fermentation of agroresources, or by Ring Opening Polymerization (ROP) of lactide, a cyclic ester derived from oligomerization-cyclization of lactic acid. Although the second synthetic route requires an additional step, it allows the formation of poly(lactic acid) of higher molecular weights and is most commonly employed in industry.1 Among ROP methods, coordination-insertion polymerization monitored by metal-based catalysts is a powerful and versatile technique, allowing access to well-defined high molecular weight polymers. One of the most efficient metal-based catalyst is tin octoate which is used for the industrial production of PLA. The latter has also been shown to be highly active for the polymerization of L-lactide by reactive extrusion, a green process allowing the continuous polymerization of a monomer without solvent.2 With the aim of developing catalysts involving low-toxicity metals which could be used in reactive extrusion process, we have demonstrated that some lanthanide-based complexes were efficient catalysts able to form macrocyclic poly(lactic acid) in a continuous way.3 We also reported the production of novel hybrid PLLA by use of a titanium oxo-cluster, acting both as a catalyst and crosslinking agent of the polymer matrix, leading to PLLA with superior dimensional stability under heat compare to the commercial polymer of same molar mass.4

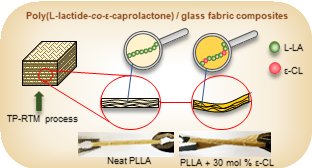

More recently, we have been focusing our research on the developpement of PLLA-based composites in one step process via Thermoplastic Resin Transfer Molding (TP-RTM). This specific process relies on the injection, into a mold containing fibers, of a monomer and a catalyst in order to carry out the polymerization of the matrix in situ.5 The major advantage over conventional melt processes is the possibility of reaching a high amount of fibers while improving their wetting by the matrix. While a wide selection of thermosetting matrix resins are available on the market for RTM process, there are only a few commercial resins for thermoplastic matrices. Although work has been carried out in TP-RTM with e-caprolactone,6 composites with a polylactide matrix via this process had never been described, due to the lock linked to the solid state of the monomer at room temperature (initiation of polymerization before injection into the mold during the melting phase in the presence of the catalyst). Recent work carried out at UMET made it possible to obtain the first prototypes of PLLA/glass fiber composites with different reinforcement rates.7 Current work aimed at strengthening the mechanical properties of the PLLA matrixby producing a novel family of composites with PLLA-based copolymer matrices, by copolymerization of L-LA with e-caprolactone.8

1. O. Dechy-Cabaret, B. Martin-Vaca, D. Bourissou, Chem. Rev. 2004, 104, 6147.

2. (a) S. Jacobsen, H.G. Fritz, Ph. Degée, P. Dubois, R. Jérôme. Polymer 2000, 41, 3395. (b) M-O Augé, D. Roncucci, S. Bourbigot, F. Bonnet, S. Gaan, Gaëlle Fontaine. Eur. Polym. J. 2023, 184, 111727.

3. F. Bonnet, F. Stoffelbach, G. Fontaine, S. Bourbigot. RSC Adv. 2015, 5, 31303.

4. E. Louisy, S. Bellayer, G. Fontaine, L. Rozes, F. Bonnet. Eur. Polym. J. 2020, 122, 109238.

5. B. Campos, S. Bourbigot, G. Fontaine, F. Bonnet, Polym. Compos. 2022, 43, 2485.

6. T. J. Corden, I. A. Jones, C. D. Rudd, P. Christian, S. Downes. Compos Part A. Appl Sci Manuf. 1999, 30, 737.

7. E. Louisy, F. Samyn, S. Bourbigot, G. Fontaine, F. Bonnet. Polymers, 2019, 11, 339.

8. (a) B. Miranda Campos, G. Fontaine, S. Bourbigot, G. Stoclet, F. Bonnet. ACS Appl. Polym. Mater, 2022, 4, 6797. (b) B. Miranda Campos, J. Beauvois, G. Fontaine, S. Bourbigot, G. Stoclet, F. Bonnet. Polym. Compos. 2025, https://doi.org/10.1002/pc.70652.

Biography:

Fanny Bonnet got her PhD on organolanthanide complexes for diene/olefin (co-)polymerization catalysis in 2003 at the University of Burgundy in France under the supervision of Dr D. Barbier-Baudry. Then she spent two years in Pr P. Mountford group in Oxford University as a postdoc researcher to develop borohydride-based catalysts for the ROP of cyclic esters. In 2005 she got a researcher position at CNRS and joined the UCCS laboratory in Lille to develop rare earth-based complexes for polymerization catalysis, and got her habilitation in 2014. In 2018, she joined UMET laboratory to work on reactive processes for the valorization of biopolymers and biocomposites, and in particular via reactive extrusion and TP-RTM. She became CNRS research director in 2022. She was the general secretary of the French Polymer Group (GFP) from 2023-2025, and is currently an elected member at CoNRS of CNRS Chemistry (scientific committee and 13 scientific section).